Rufin famfo

1, tururi hadawan abu da iskar shaka: famfo a cikin high zafin jiki ruwa tururi, saman da samuwar wani oxide fim, da coolant adsorption ne mai kyau, na iya taka rawa wajen rage gogayya, yayin da hana famfo da yankan abu tsakanin bond, dace. don sarrafa m karfe.

2, nitriding jiyya: famfo nitriding nitriding, forming wani surface hardening Layer, dace da sarrafa simintin gyaran kafa ƙarfe, jefa aluminum da sauran kayan a kan kayan aiki lalacewa.

3, tururi + nitriding: cikakken fa'idodin na sama biyu.

4, TiN: zinariya rawaya shafi, mai kyau shafi taurin da lubricity, da kuma shafi mannewa yi yana da kyau, dace da sarrafa mafi yawan kayan.

5, TiCN: shuɗi launin toka shafi, taurin game da 3000HV, zafi juriya na 400 ° C.

6, TiN + TiCN: launi mai launin rawaya mai duhu, tare da ingantaccen tauri da lubricity, dace da sarrafa yawancin kayan.

7, TiAlN: shuɗi launin toka shafi, taurin 3300HV, zafi juriya har zuwa 900 ° C, za a iya amfani da high-gudun aiki.

8, CrN: murfin launin toka na azurfa, aikin lubrication yana da kyau, galibi ana amfani dashi don sarrafa karafa marasa ƙarfe.

Rufin famfo yana da tasiri mai mahimmanci akan aikin famfo, amma a halin yanzu, masu sana'a da masu sana'a suna aiki tare da juna don nazarin abin da ke ciki na musamman, kamar LMT IQ, Walther THL, da dai sauransu.

Abubuwan da ke shafar taɓawa

A. Kayan aiki na bugawa

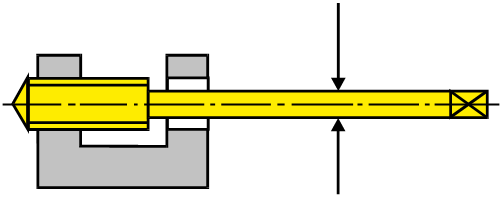

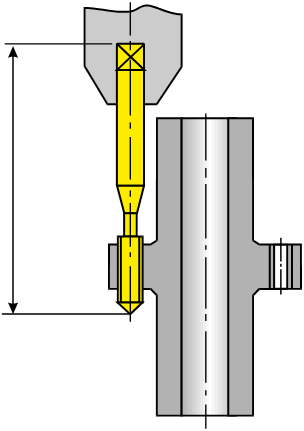

1. Kayan aiki na na'ura: ana iya raba shi zuwa hanyoyin sarrafawa na tsaye da a kwance.Don bugawa, a tsaye ya fi aiki a kwance, kuma aiki a kwance ya kamata a yi la'akari da ko sanyaya ya wadatar.

2, tapping shank: ana bada shawarar yin amfani da tapping shank na musamman, ƙarfin injin, ingantaccen kwanciyar hankali ya fi dacewa don zaɓar ƙwanƙwasawa mai daidaitawa, akasin haka, gwargwadon yadda zai yiwu don zaɓar madaidaicin tapping shank tare da ramuwa axial / radial.Yi amfani da motar murabba'i a duk lokacin da zai yiwu, ban da ƙananan famfo diamita (

3. Yanayin kwantar da hankali: don bugawa, musamman maɗaukaki na extrusion, abin da ake bukata don sanyaya shine lubrication> sanyaya;A cikin ainihin amfani, ana iya shirya shi bisa ga yanayin kayan aikin injin (lokacin amfani da emulsion, ana bada shawarar cewa maida hankali ya fi 10%).

B. The workpiece da za a sarrafa

1. Kayan aiki da taurin kayan aikin da aka sarrafa: ƙarfin kayan aiki ya kamata ya zama uniform.Yawancin lokaci ba a ba da shawarar yin amfani da famfo don sarrafa kayan aikin fiye da HRC42 ba.

2, tapping kasa rami: kasa rami tsarin, zabi dama bit;Matsakaicin girman rami na ƙasa;Girman bangon rami na ƙasa.

C. Tsarin sarrafawa

1, saurin gudu: ana ba da sauri bisa ga nau'in famfo, kayan aiki, kayan sarrafawa da taurin, amfani da rashin amfani na kayan aiki na kayan aiki.

Yawancin lokaci ana zaɓa bisa ga sigogin da mai yin famfo ya bayar, dole ne a rage saurin a ƙarƙashin yanayi masu zuwa:

▶ rashin ƙarfi na inji ba shi da kyau;Babban bugun famfo;Rashin isasshen sanyi;

▶ Buga kayan wuri ko taurin ba iri ɗaya ba ne, kamar haɗin gwiwa;

▶ Ana tsawaita famfo, ko kuma a yi amfani da sandar tsawo;

▶ Kwance, sanyi a waje;

▶ Aikin hannu, kamar rawar benci, rawar rocker, da sauransu;

2, ciyarwa: tatsi mai tsauri, ciyarwa = 1 farar/juyawa.

Taɓa mai sassauƙa, kuma madaidaicin ramuwar shank ya wadatar:

Ciyarwa = (0.95-0.98) farar / juyin juya hali.

Wasu shawarwari akan zaɓin famfo

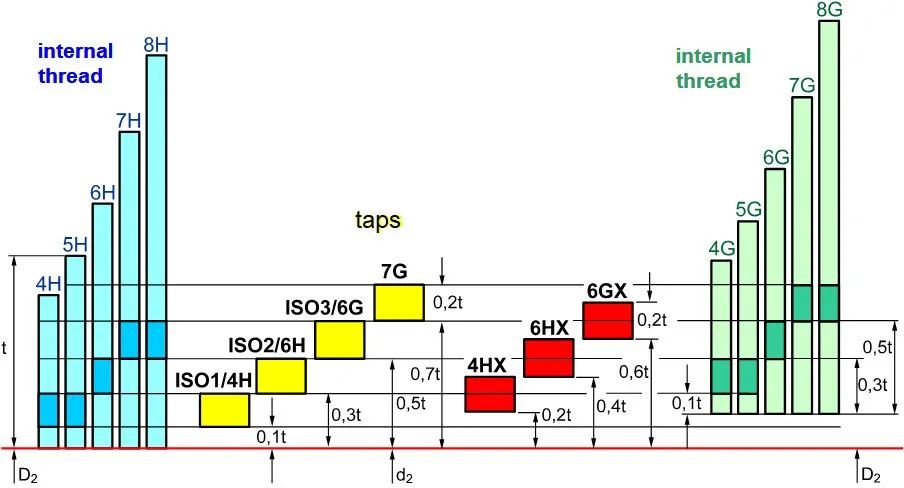

A. Hakuri na famfo na ma'auni daban-daban

Tushen zaɓi: ba kawai bisa ga madaidaicin madaidaicin zaren da za a naɗa don zaɓar da tantance madaidaicin ƙimar famfo ba.

▶ Kayan aiki da taurin kayan aikin da aka sarrafa;

▶ Kayan aiki na taɓawa (kamar yanayin injin, ƙulli, zoben sanyaya, da sauransu);

▶ Matsa kanta daidaito da kuskuren masana'anta.

Misali: sarrafa zaren 6H, a cikin sarrafa ƙarfe, na iya zaɓar madaidaicin famfo na 6H;A cikin tsarin simintin simintin launin toka, saboda tsakiyar diamita na famfo yana da sauri, fadada ramin dunƙule yana da ƙananan, don haka ya dace don zaɓar madaidaicin famfo na 6HX, rayuwa zata fi kyau.

Lura akan daidaiton famfo na Japan:

▶ Yankan famfo OSG yana amfani da daidaitaccen tsarin OH.Daban-daban da daidaitattun ISO, tsarin daidaitaccen tsarin OH yana tilasta duk faɗin band ɗin haƙuri daga mafi ƙanƙanci, kowane 0.02mm azaman matakin daidaitaccen, mai suna OH1, OH2, OH3, da sauransu.

▶ Extrusion famfo OSG yana amfani da daidaitaccen tsarin RH, daidaitaccen tsarin RH zai tilasta duk faɗin haƙuri daga mafi ƙasƙanci, kowane 0.0127mm azaman matakin daidaitaccen, mai suna RH1, RH2, RH3 da sauransu.

Don haka, lokacin maye gurbin madaidaicin fam ɗin OH tare da madaidaicin fam ɗin ISO, bai kamata a ɗauki 6H a matsayin kusan daidai da matakin OH3 ko OH4 ba.Ya kamata a ƙayyade ta hanyar juyawa ko bisa ga ainihin halin da abokin ciniki ke ciki.

B. Girman waje na famfo

1. A halin yanzu, mafi yawan amfani da su sune DIN, ANSI, ISO, JIS, da dai sauransu.

2, bisa ga abokin ciniki ta daban-daban aiki bukatun ko data kasance yanayi zabi dace tsawon, ruwa tsawon da rike square size.

3. Tsangwama yayin aiki;

Matsa zaɓin abubuwa na asali guda shida

1, nau'in zaren sarrafawa, metric, Burtaniya, Amurka, da sauransu;

2. Nau'in rami na kasa na zaren, ta rami ko makaho;

3, sarrafa workpiece abu da taurin;

4, da workpiece cikakken thread zurfin da kasa rami zurfin;

5, workpiece thread daidaici;

6, bayyanar ma'aunin famfo (buƙatun na musamman suna buƙatar alama).

Lokacin aikawa: Satumba-22-2022